Swab And Surge In Drilling Definition & Calculations

Surging or swabbing pressures in drilling describe pressure changes in the annulus resulting from pipe movement. The swabbing occurs when the drill pipe is pulled from the well, which will force mud flows down the annulus to fill the void left by the pipe. But the surging occurs when the drill pipe is lowered into the well, then the mud is forced out of the flow line.

https://www.drillingmanual.com/surge-and-swab-pressure-calculations-drilling/

Saturday, 22 July 2023

Friday, 21 July 2023

Directional Drilling Surveying Tools

The oldest surveying tool for directional drilling was known as an acid bottle. When taking a survey, the tool aligned itself with the hole's axis, but the surface of the acid remained level. The instrument was left in this position for about 30 minutes, allowing the acid to etch a sharp line on the glass container, which indicated the hole angle.

This system did not, however, determine the direction of the wellbore.

https://www.drillingmanual.com/directional-drilling-surveying-tools/

The oldest surveying tool for directional drilling was known as an acid bottle. When taking a survey, the tool aligned itself with the hole's axis, but the surface of the acid remained level. The instrument was left in this position for about 30 minutes, allowing the acid to etch a sharp line on the glass container, which indicated the hole angle.

This system did not, however, determine the direction of the wellbore.

https://www.drillingmanual.com/directional-drilling-surveying-tools/

Thursday, 20 July 2023

Stripping Operation In Oil & Gas Well Control

Application

During operations on drilling or producing well, a sequence of events may require tubing, casing, or drill pipe to be run or pulled while annular pressure is contained by blowout preventers; such practice is called “stripping operation”. Stripping is normally considered an emergency procedure to maintain well control; however, plans for certain drilling, completion, or well workover operations may include stripping to eliminate the necessity of loading the well with fluid.

https://www.drillingmanual.com/stripping-operations/

Application

During operations on drilling or producing well, a sequence of events may require tubing, casing, or drill pipe to be run or pulled while annular pressure is contained by blowout preventers; such practice is called “stripping operation”. Stripping is normally considered an emergency procedure to maintain well control; however, plans for certain drilling, completion, or well workover operations may include stripping to eliminate the necessity of loading the well with fluid.

https://www.drillingmanual.com/stripping-operations/

Gyro Tool For Surveying In Oil & Gas Drilling Wells

This article discusses gyro wellbore survey tool services available today in the oil and gas industry beginning with basic gyroscopic theory and leading up to Rate Gyro technology. There is no attempt to compare systems or provide an expert technical description of any company’s technology. The intent is rather to provide a basic understanding of gyro technology, its background, goals, and place among other surveying methods.

https://www.drillingmanual.com/gyro-survey-tool-oil-gas-wireline/

This article discusses gyro wellbore survey tool services available today in the oil and gas industry beginning with basic gyroscopic theory and leading up to Rate Gyro technology. There is no attempt to compare systems or provide an expert technical description of any company’s technology. The intent is rather to provide a basic understanding of gyro technology, its background, goals, and place among other surveying methods.

https://www.drillingmanual.com/gyro-survey-tool-oil-gas-wireline/

Wednesday, 19 July 2023

Well Control Methods In Oil & Gas Guide

To cover the methods of well control for fixed rigs, cover the special considerations for subsea rigs (Types of drilling rigs), and look at step-down graphs for deviated and horizontal wells.

General Well Control Methods

The objective of the various kill methods is to circulate out any invading fluid and circulate a satisfactory weight of kill mud into the well without allowing further fluid into the hole. Ideally, this should be done with the minimum of damage to the well.

https://www.drillingmanual.com/methods-of-well-control/

To cover the methods of well control for fixed rigs, cover the special considerations for subsea rigs (Types of drilling rigs), and look at step-down graphs for deviated and horizontal wells.

General Well Control Methods

The objective of the various kill methods is to circulate out any invading fluid and circulate a satisfactory weight of kill mud into the well without allowing further fluid into the hole. Ideally, this should be done with the minimum of damage to the well.

https://www.drillingmanual.com/methods-of-well-control/

Magnetic Multishot Survey Tool Instrument

At specific points in the well, it is helpful to determine the overall trajectory (Check directional survey calculations excel sheet) in a single survey run (e.g., just before running casing). This is usually done by a Directional Magnetic Multi shot Survey Tool which takes a series of pictures. It also can be dropped from surface or run on W/L.

Magnetic Multishot Survey Tool

A magnetic multi-shot works on the same principle as a magnetic single shot, but has a particular camera unit.

https://www.drillingmanual.com/directional-magnetic-multi-shot-survey-tool/

At specific points in the well, it is helpful to determine the overall trajectory (Check directional survey calculations excel sheet) in a single survey run (e.g., just before running casing). This is usually done by a Directional Magnetic Multi shot Survey Tool which takes a series of pictures. It also can be dropped from surface or run on W/L.

Magnetic Multishot Survey Tool

A magnetic multi-shot works on the same principle as a magnetic single shot, but has a particular camera unit.

https://www.drillingmanual.com/directional-magnetic-multi-shot-survey-tool/

Tuesday, 18 July 2023

Volumetric Well Control Method For Gas Kicks

The volumetric method is mostly used in workover and production well control operations. It is a means of allowing the gas to migrate (gas kick behaviour) to the surface under control. The gas needs to migrate at over (approx.) 1000' per hour.

To allow the bubble to expand the casing pressure is held constant for a given volume of mud bled off. This operation is repeated, holding an ever-increasing casing pressure until the gas reaches the surface (Holding Bottom Hole Pressure constant).

https://www.drillingmanual.com/volumetric-well-control/

The volumetric method is mostly used in workover and production well control operations. It is a means of allowing the gas to migrate (gas kick behaviour) to the surface under control. The gas needs to migrate at over (approx.) 1000' per hour.

To allow the bubble to expand the casing pressure is held constant for a given volume of mud bled off. This operation is repeated, holding an ever-increasing casing pressure until the gas reaches the surface (Holding Bottom Hole Pressure constant).

https://www.drillingmanual.com/volumetric-well-control/

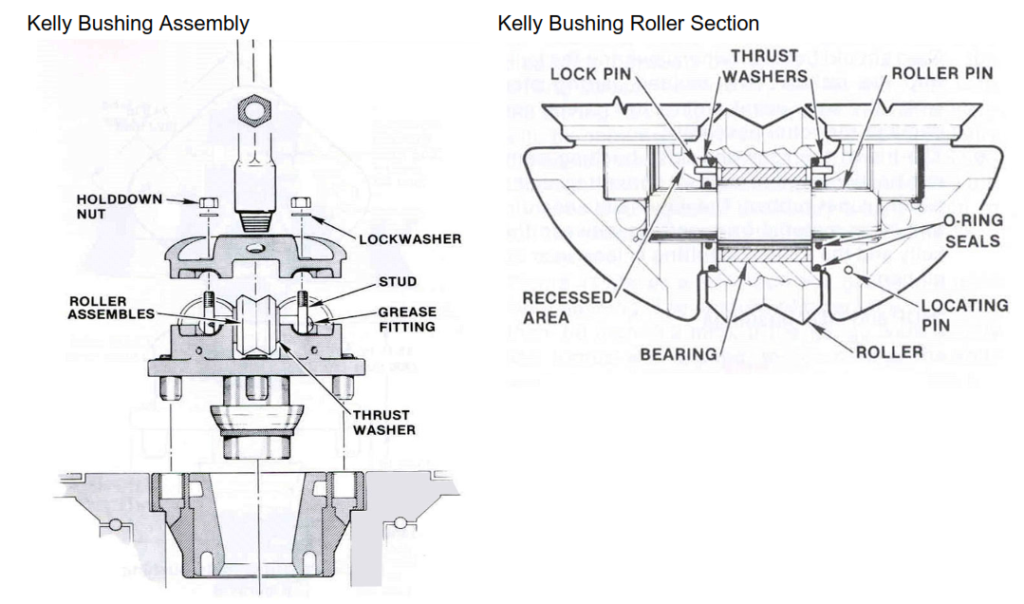

Kelly Bushing In Oil & Gas Rigs Simple Guide

The Kelly drive bushing engages the master bushing in the rotary (either square drive or pin drive). As the rotary turns, the Kelly drive bushing turns with it to drive the Kelly. At the same time, as the Kelly works down, the rollers in the bushing allow the Kelly free movement and keep it centered in the rotary bore. In other words, it serves as a connection point between the rotary table and the drill string, enabling power transmission from the rotary table to the drill bit.

https://www.drillingmanual.com/kelly-drive-bushing/

Magnetic Single Shot Survey Tool Instrument

The magnetic single shot survey tool instrument was first used in the 1930s for measuring the inclination and direction of a well. Here we shall explain its mechanism and components.

Application

Single-Shot surveys, which photograph the instrument at a single position, are often used by the directional driller to track the drilling bit’s progress while drilling is underway. The compass unit of a magnetic survey instrument is placed in a non-magnetic drill collar (NMDC)

https://www.drillingmanual.com/magnetic-single-shot/

The magnetic single shot survey tool instrument was first used in the 1930s for measuring the inclination and direction of a well. Here we shall explain its mechanism and components.

Application

Single-Shot surveys, which photograph the instrument at a single position, are often used by the directional driller to track the drilling bit’s progress while drilling is underway. The compass unit of a magnetic survey instrument is placed in a non-magnetic drill collar (NMDC)

https://www.drillingmanual.com/magnetic-single-shot/

Monday, 17 July 2023

Wait And Weight Method For Killing Operations

What Is Wait & Weight Killing Method?

The Wait and Weight is sometimes referred to as the Engineer's Method or the One Circulation Method. It does, at least in theory, kill the well in one circulation.

Once the well is Shut In (hard shut-in well procedure - Soft shut-in procedure) and pressures stabilized, the Shut-In Drill Pipe pressure is used to calculate the kill mud weight. When ready, Kill mud is pumped down the Drill Pipe.

https://www.drillingmanual.com/the-wait-and-weight-method/

What Is Wait & Weight Killing Method?

The Wait and Weight is sometimes referred to as the Engineer's Method or the One Circulation Method. It does, at least in theory, kill the well in one circulation.

Once the well is Shut In (hard shut-in well procedure - Soft shut-in procedure) and pressures stabilized, the Shut-In Drill Pipe pressure is used to calculate the kill mud weight. When ready, Kill mud is pumped down the Drill Pipe.

https://www.drillingmanual.com/the-wait-and-weight-method/

Good Practice Procedures

Driving Conductor Pipe

30" CP Driving Procedure

Hammering Operations (Final Refusal Depth)

Drilling Operations

Drilling Casing Flotation Equipment With PDC Bits

General Drilling Guidelines

Drilling Problems and Proposed Precautionary Measures

Mud Motor operations

Drilling Bits

PDC Bit Drilling Parameters

Running PDC Bit

Drill Off Test

Operating Procedures For Roller Cone Bits

Casing Running and Cementing

Casing Running and Cementing Preparation

Casing running - installation

https://www.drillingmanual.com/good-practice-procedures/

Driving Conductor Pipe

30" CP Driving Procedure

Hammering Operations (Final Refusal Depth)

Drilling Operations

Drilling Casing Flotation Equipment With PDC Bits

General Drilling Guidelines

Drilling Problems and Proposed Precautionary Measures

Mud Motor operations

Drilling Bits

PDC Bit Drilling Parameters

Running PDC Bit

Drill Off Test

Operating Procedures For Roller Cone Bits

Casing Running and Cementing

Casing Running and Cementing Preparation

Casing running - installation

https://www.drillingmanual.com/good-practice-procedures/

Sunday, 16 July 2023

Driller's Method In Well Control Procedures & Calculations

https://www.youtube.com/watch?v=oA_qbss10Po

In Driller's Method, the Kill is split into two circulations to fully control the well.

- During the first, the Kick fluid is circulated without changing the mud weight.

- During the second, once the Kick is out, the mud is weighted up and pumped around the well on the second circulation.

https://www.drillingmanual.com/methods-of-well-control-drillers-method/

https://www.youtube.com/watch?v=oA_qbss10Po

In Driller's Method, the Kill is split into two circulations to fully control the well.

- During the first, the Kick fluid is circulated without changing the mud weight.

- During the second, once the Kick is out, the mud is weighted up and pumped around the well on the second circulation.

https://www.drillingmanual.com/methods-of-well-control-drillers-method/

How To Be a Successful Drilling Supervisor In Oil & Gas Rigs

The role of a drilling supervisor is crucial in ensuring the efficient execution of drilling activities in the oil and gas rigs. As a supervisor, they oversee the daily drilling activities, manage the drilling rig crew, and coordinate with drilling contractors and service providers. They are also responsible for ensuring the safety of the drilling operation by enforcing safety rules and procedures and ensuring a safe work environment for the crew.

https://www.drillingmanual.com/drilling-rig-supervisor-job-description/

Liner Running, Setting And Cementing Procedures

The liner hanger system is installed at the top of the casing liner (One of Types Of Casing). The function of the liner hanger is to hang and suspend the liner. There are mechanical liner hanger and hydraulic set hangers. In this article, we will provide detailed steps for Liner Hanger Setting & Cementing Procedures.

The main two types of Liner Hanger are:

- Mechanical liner hangers require manipulation of the Drill Pipe (Check

https://www.drillingmanual.com/liner-running-procedures/

The liner hanger system is installed at the top of the casing liner (One of Types Of Casing). The function of the liner hanger is to hang and suspend the liner. There are mechanical liner hanger and hydraulic set hangers. In this article, we will provide detailed steps for Liner Hanger Setting & Cementing Procedures.

The main two types of Liner Hanger are:

- Mechanical liner hangers require manipulation of the Drill Pipe (Check

https://www.drillingmanual.com/liner-running-procedures/

Saturday, 15 July 2023

Kill Mud Weight Calculations In Oil & Gas

Kill Mud is the drilling fluid with a specific weight that will restore the primary well control and will secure the well on its own without the need of closing the BOP stack or any secondary well control.

Balance of Pressures

Once the well is shut-in providing nothing has broken down, the pressures in the well will be in balance. What is lacking in hydrostatic head of fluid in the well is now being made up by surface applied pressure on the annulus and on the drill pipe.

https://www.drillingmanual.com/kill-mud-weight-calculations/

Kill Mud is the drilling fluid with a specific weight that will restore the primary well control and will secure the well on its own without the need of closing the BOP stack or any secondary well control.

Balance of Pressures

Once the well is shut-in providing nothing has broken down, the pressures in the well will be in balance. What is lacking in hydrostatic head of fluid in the well is now being made up by surface applied pressure on the annulus and on the drill pipe.

https://www.drillingmanual.com/kill-mud-weight-calculations/

Rotary Steerable System In Directional Wells

Rotary Steerable System RSS represents an evolutionary step forward in directional drilling technology, overcoming the drawbacks of steerable motors and conventional rotary BHA types. In steerable motors, to initiate a change in the wellbore trajectory, halt the rotation in such a position that the bend in the motor points toward the new trajectory. This mode, known as the sliding mode, typically creates higher frictional forces on the drill string.

https://www.drillingmanual.com/rss-rotary-steerable-system/

Rotary Steerable System RSS represents an evolutionary step forward in directional drilling technology, overcoming the drawbacks of steerable motors and conventional rotary BHA types. In steerable motors, to initiate a change in the wellbore trajectory, halt the rotation in such a position that the bend in the motor points toward the new trajectory. This mode, known as the sliding mode, typically creates higher frictional forces on the drill string.

https://www.drillingmanual.com/rss-rotary-steerable-system/

Subscribe to:

Comments (Atom)